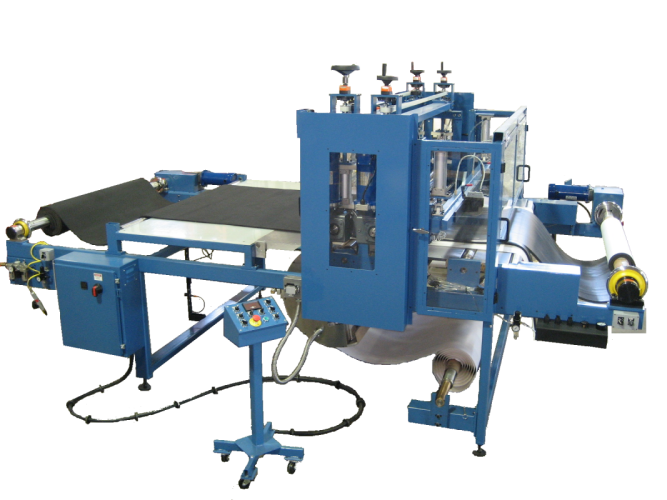

Relco has been manufacturing high quality industrial laminators for decades. In that time we have realized that our customers require laminators which meet their specific needs (such as PSA laminators), not only for their current production demands but also for their vision for future growth and expansion. Accordingly, our dedicated engineering staff will work together with you to create a laminator which has all the features to help you make perfectly laminated sheets and rolls. Relco’s aim is to help you meet today’s demands as well as tomorrow’s.

Our machines support laminating materials to pressure sensitive adhesive (PSA) as well as laminating two materials with an adhesive. Relco has fully leveraged the power of modern electronics and brought the intelligence of computers and servo systems to the industrial laminating process. The result is consistent lamination without any compromises; quality is guaranteed.

Key Features and Options Include:

- Conveyorizied In-Feed and Out-Feed

- Powered Adjustable Unwind

- Heated Rollers

- Infra-Red Heating

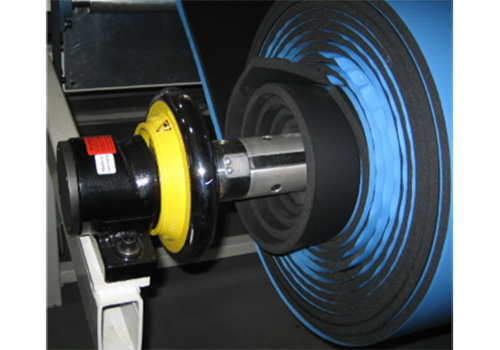

- Drum PSA heating

- Servo Controlled Nip Area

- Overdrive and Underdrive Prelamination Rollers

- Computerized Recipe Control – with “on-the-fly” recipe capture

- Variety of Sheeting Options

- Crash Slitting

- Through Slitting

- Tension Controlled Rewind

- Customer and Application Focused Custom Engineering