Economy: High impact resistance, no chipping or crumbling ensure perfect cutting results, minimum wear and an extremely long service life.

Use: Suitable for all cutting applications, machines, tools, and materials, such as leather, artificial leather (also with textile backing), fabrics, textiles, synthetics, fibrous materials, fibreboard, hardboard, plywood, paper, foils, rubber, foam rubber, carpets, felt, compressed cork, asbestos, and various other materials; also suitable for perforating work.

Dimensions: Available in all sizes within 4,000 x 2,000 mm in thickness of 3/8″ , 1/2″ and 7/8″. Boards in larger sizes or other thickness available upon request.

Designs: Both surfaces planed for alternate cutting on either side or with roughened back, ready for cement bonding.

“Natural” Board

| Properties | Unit | Testing Method | Value |

|---|---|---|---|

| Density | g/cm3 | DIN 53 479 | 0.91 |

| Yield extension | N/mm2 | DIN 53 455 | 31 |

| Ultimate tensile strength | N/mm2 | DIN 53 455 | 34 |

| Elongation at break | % | DIN 53 455 | 700 |

| Impact strength | mJ/mm2 | DIN 53 455 | no breaking |

| Nothced impact strength | mJ/mm2 | DIN 53 455 | 11 |

| Brinell hardness (30 sec) | N/mm2 | DIN 53 455 | 63 |

| Tolerance in thickness | mm | +/- 0.2 | |

| Tolerance per square meter | mm | +/- 1.0 | |

| Hardness (Shore D) | DIN 53 505 | 75 |

“Grey” Boards

| Properties | Unit | Testing Method | Value |

|---|---|---|---|

| Density | g/cm3 | DIN 53 479 | 0.91 |

| Yield extension | N/mm2 | DIN 53 455 | 30-35 |

| Ultimate tensile strength | N/mm2 | DIN 53 455 | 36-40 |

| Crystaline melting range | Centigrades | 165 | |

| Nothced impact strength | mJ/mm2 | DIN 53 455 | 37-47 |

| Brinell hardness (30 sec) | N/mm2 | DIN 53 455 | 65-75 |

| Tolerance in thickness | mm | +/- 0.2 | |

| Tolerance per square meter | mm | +/- 2.0 | |

| Hardness (Shore D) | DIN 53 505 | 74 |

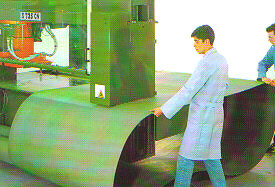

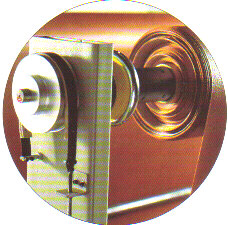

When needed, the belts can be changed quickly and easily, removing and replacing is done from the side of the machines with minimum disruption.

Long belt life is attained owing to a special belt shifting device, automatic setting of mechanical positive stop and minimum deflection of the press, all found on RELCO/ATOM cutting systems.

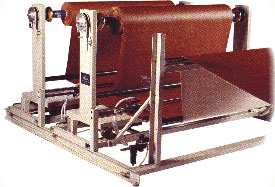

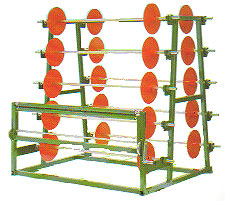

- Multiple rolls design

- Various roll sizes

- Driven unwind

- Driven rewind

- Custom designs available

Individual roll edge alignment.

Multiple rolls aligned and combined with an edge accuracy of plus or minus 1/16″.

Adjustable brake band to control material tension, a quick change air shaft, and safety chucks.

- The simplest and fastest solution for handling material in rolls.

- The roll-holders are mounted on wheels for quick interchange of material.

- A locking device keeps it in place automatically.

- Friction rolls avoid disruption of material alignment during operations.

- A change of material can be performed in less than two minutes.